Product Description

Product Description:

1) Material: Gray Iron, Ductile Iron.

2) Process:Resin sand casting.

3) Applied software for specification drawings: Pro/E, AutoCAD, Solidworks etc.

4) Facility: Electric furnace, cupola furnace, anneal furnace, sand mixing machine, shot blast chamber, various molding machine.

5) Precision machining: CNC, NC lathes, boring machines, milling machines, bench drilling machines, etc.

6) Surface Protection: oiled (rust-proof), electroplating, hot dip galvanizing, nickel or chrome plating, painting, powder coating.

7) Products’ location: The special designed fittings, widely used in municipal and drainage system, power station, industrial equipment, vehicles, etc.

Our Inspection Equipment:

Direct-reading spectrograph,metallographic microscope,hardness tester,brinell hardness tester,thermometric indicator,universal testing machine,carbon and silicon analysis meter,magnetic powder flaw detector,digital ultrasonic flaw detector etc.

Our Service:

1)Your inquiry related to our products or prices will be replied in 12 hours.

2)Individual formula according to customers’ special drawing requests.

3)Manufacturer with large capacity,ensures the fast production cycle after

confirming the order.

4)Protection of sales area and private information for all of our customers.

HangZhou CHINAMFG Machinery Co.,Ltd is 1 famous company in China which specialized in various metal casting products with over 10 years experience located in HangZhou China.It covers a comprehensive range of casting and machining and was widely used in Agriculture machinery, Motor Vehicle, Architecture,Railway and Engineering

As a professional company, CHINAMFG have 4 groups of experienced teams to be in charge of different work:

Project team-customer service

Engineering team-provide R&D and technical support

QC team-productive process control and incoming parts inspection

Warehouse team-warehouse management and logistic service

Quality Control:

We have a full set of quality control system to guarantee best product quality. Depending on the products, we can make different Item Testing Plan, Manufacturing procedure etc.

Raw material control

Chemistry spectrum analysis

Mechanical property

Metallographic analysis

Ultrasonic testing

Magnetic testing

Radiographic testing

Dimension inspection

Visual inspection

Penetrant testing

Leak testing

Hardness test

Micro-structure tester after heat treatment

Machining Ability

Our machining shop located in HangZhou using the latest CNC equipment to provide our customer with high quality products.

Horizontal and Vertical Machining Center

CNC lathe and normal lathe

CNC drilling and milling Center

Other assistant equipment

| PROCESS | MATERIAL | STHangZhouRD | |

| SAND CASTING |

Green Sand | Grey Iron, Ductile Iron, Malleable Iron, Stanless Steel, Carbon, Steel, Aluminium, Brass, Bronze | ASTM BS JIS DIN etc |

| Furan Resin Sand | |||

| Cold Harden Resin Sand | |||

| INVESTMENT CASTING |

Sodium Silicone (Water galss) | Stainless Steel, Carbon Steel, Special Alloy Steel Bronze, Brass, Aluminum | |

| Silica Sol | |||

| FORGING | Hammer Forging | Stainless Steel, Carbon Steel, Alloy Streel, Brass, Aluminum | |

| Die Forging | |||

| Roll Forging | |||

| STAMPING MACHINING | STAMPING MACHINING | All metal material | |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Type: | Clay Wet Sand |

|---|---|

| Casting Method: | Thermal Gravity Casting |

| Sand Core Type: | Resin Sand Core |

| Application: | Machinery Parts |

| Machining: | CNC Machining |

| Material: | Iron |

| Customization: |

Available

| Customized Request |

|---|

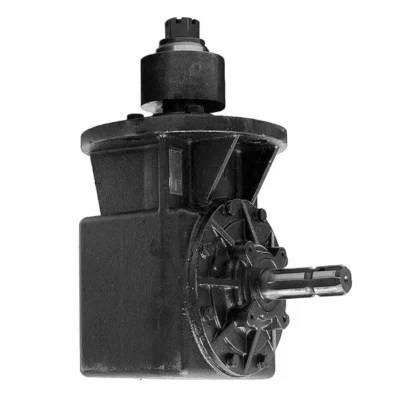

Design for Heavy-Duty Use: How Rotary Cutter Gearboxes Withstand Rigors

Rotary cutter gearboxes are engineered with robust features to ensure durability and withstand the demands of heavy-duty use:

- High-Quality Materials: These gearboxes are constructed using high-strength materials, such as alloy steels and hardened components, to withstand the stresses of cutting tough vegetation and materials.

- Sturdy Housing: The gearbox housing is designed to provide protection to internal components and resist impact and external forces during operation.

- Sealed Bearings: Sealed bearings prevent dirt, debris, and moisture from entering the gearbox, ensuring smooth and reliable operation even in challenging environments.

- Reinforced Gears: The gears within rotary cutter gearboxes are precision-cut and heat-treated for added strength and wear resistance, allowing them to handle heavy loads and repeated stresses.

- Enhanced Cooling: Some designs incorporate cooling features, such as fins or cooling channels, to dissipate heat generated during operation and maintain optimal gearbox temperature.

- Secure Mounting: Rotary cutter gearboxes are designed to be securely mounted to the machinery, minimizing vibrations and ensuring consistent performance.

- Proper Lubrication: Adequate lubrication is essential to reduce friction and prevent premature wear. Some gearboxes are equipped with efficient lubrication systems to ensure consistent and sufficient lubrication.

- Rigorous Testing: Manufacturers subject rotary cutter gearboxes to rigorous testing procedures to simulate heavy-duty conditions and ensure they meet performance and reliability standards.

By incorporating these design elements, rotary cutter gearboxes are capable of enduring the challenging conditions of heavy-duty use, providing reliable cutting power and contributing to the efficient operation of various equipment.

Handling Cutting Speeds and Blade Configurations in Rotary Cutter Gearboxes:

Rotary cutter gearboxes are designed to accommodate various cutting speeds and blade configurations to suit different tasks and conditions. The gearbox’s gear ratio, which determines the output speed relative to the input speed, can be optimized for specific cutting requirements. Different blade configurations, such as the number and arrangement of cutting blades, can also be accommodated by adjusting the gearbox’s design.

For example, gearboxes with adjustable gear ratios allow operators to select the appropriate cutting speed based on factors like the type of vegetation and desired cutting results. Additionally, rotary cutter gearboxes can be equipped with different output shafts or adapters to fit various blade configurations, including single or multiple blades. This versatility enables rotary cutter gearboxes to effectively handle a wide range of cutting tasks in agricultural, landscaping, and land management applications.

Rotary Cutter Gearbox: Function and Applications

A rotary cutter gearbox is a mechanical device designed to transmit and modify rotational motion between an input shaft and an output shaft. It is commonly used in various applications that require cutting or shredding, especially in agricultural, landscaping, and industrial contexts. The gearbox enables the rotary cutter to efficiently convert input power into rotary cutting motion, allowing it to perform tasks such as mowing, mulching, and clearing vegetation.

In agricultural settings, rotary cutter gearboxes are often integrated into equipment like rotary mowers, flail mowers, and brush cutters. These machines are used for maintaining fields, pastures, roadsides, and other areas by cutting down tall grass, weeds, and brush. In landscaping and groundskeeping, rotary cutter gearboxes find application in lawn mowers, brush hogs, and trimmers, contributing to well-maintained outdoor spaces.

Industrial applications of rotary cutter gearboxes include wood chippers, where they facilitate the cutting and processing of wood into smaller pieces for various purposes. They are also utilized in manufacturing and recycling processes to shred materials like plastics, rubber, and metal scraps.

The versatility of rotary cutter gearboxes stems from their ability to adapt to different cutting attachments and blades, allowing them to handle various materials and conditions. Proper selection and maintenance of rotary cutter gearboxes are essential to ensure efficient cutting performance, extend their lifespan, and maintain safe operation.

editor by CX 2024-05-07